Brake Colloquium

Link Engineering Company - Booth 402

A Global Leader in the Testing of New Technologies & Innovations

LINK is the largest brake laboratory in the world and the preferred supplier to most original equipment manufacturers. As technical lead on many global working groups, we don't just follow the standards; we set them. Since 1935, we've helped establish the brake testing specs and methodologies that have become industry norms. Whether it's durability, performance, NVH, or any of the five other test types, you can always trust LINK to deliver the smartest solution in our lab or yours, anywhere in the world.

More Than Brakes

With decades of testing experience not only in brakes, but wheel end, transmission and driveline, springs, steering, control and acquisition, HVAC, and servo dynamics, LINK is a trusted global testing partner. Our specialty has always been developing innovative custom solutions for a wide range of applications and industries, so our global testing team is committed to finding the best solution to virtually any engineering problem.

We are excited to introduce and highlight new technologies at this year's event. Find out more below!

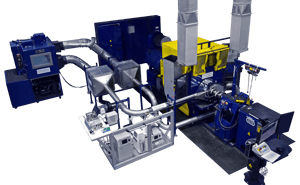

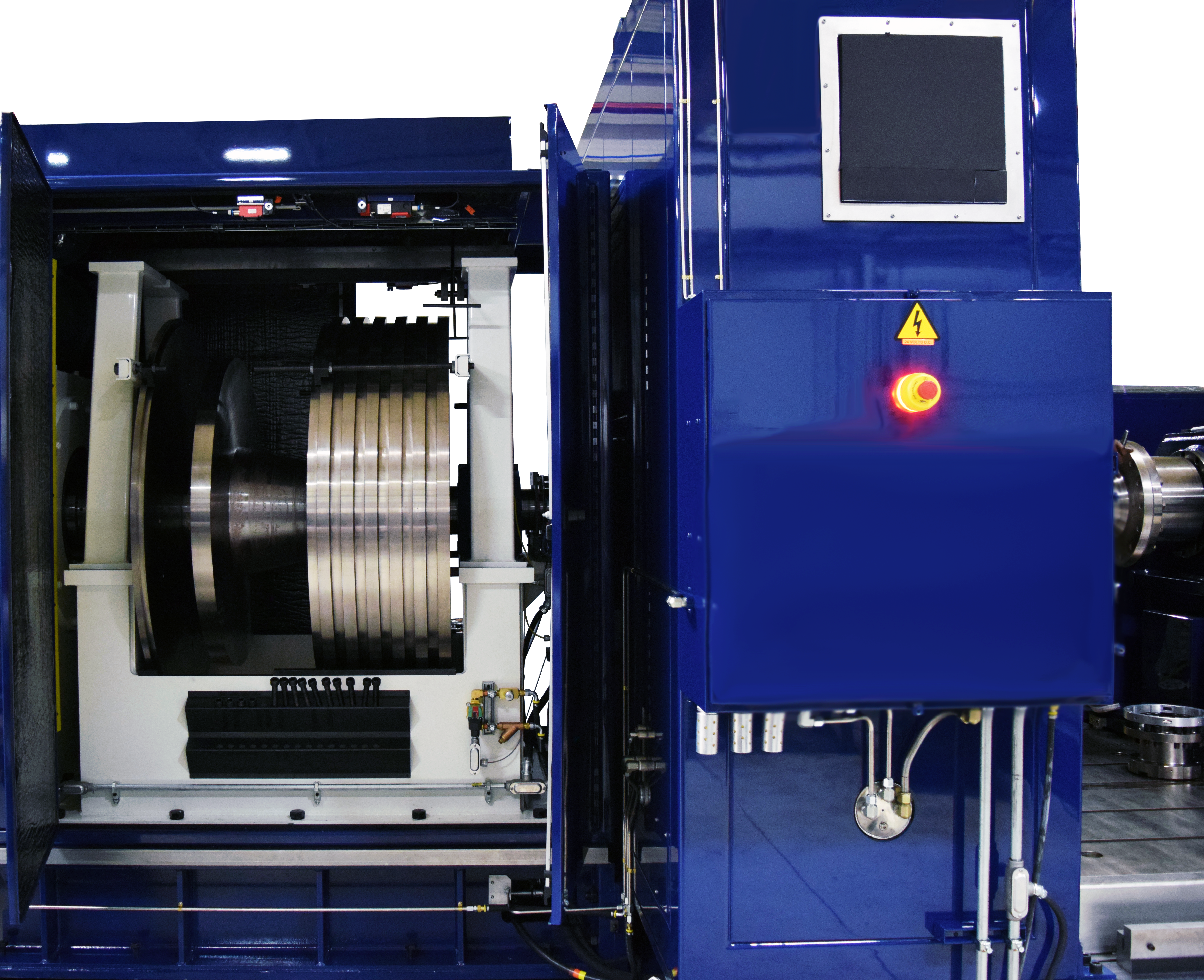

Brake Emissions

LINK is proud to be leading the way in the testing of new innovations, including brake emissions. Our Brake Emissions Test System (Model 6330) is ISO 17025 certified and is built upon several industry standards and PMP recommendations. The brake sampling system lets you replicate a duty cycle from your vehicle and collect samples of particulate matter under tightly-controlled conditions.

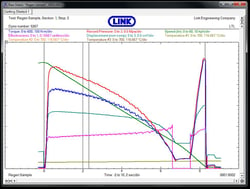

RegenSim 2.0

Through the advent of RegenSim, LINK has developed the capability to simulate regenerative braking conditions on inertia brake dynamometers. RegenSim enables the ProLINK control system to act as a vehicle’s Electronic Control Unit (ECU), distributing the amount of work to be done between the friction brake and the regenerative source.

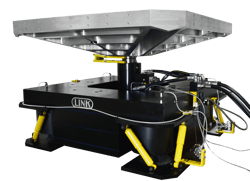

Structural Brake Testing

Structural and fatigue testing of components are critical safety issues; when critical questions related to product reliability, structural integrity, and compliance to regulations emerge is when and where LINK’s test systems and test engineers exceed. With more than 80 years of field expertise in actuation-based test systems, including vibration test stands, LINK specializes in crafting quality solutions for the structural testing industry.

Environmental and Corrosion Testing

As the provider of environmental testing solutions for numerous applications, LINK offers walk-in, reach-in, and corrosion chambers, plus portable conditioning units. Our environmental and brake dynamometer testing capabilities work together to perform environmental durability and corrosion testing of automotive components.

Plus...

- Electro-mechanical Brake Units (EMB) Testing Solutions for R&D

- Hardware in the Loop (HiL)

- Brake-by-Wire

- Model 6900 Commercial Vehicle NVH Dynamometer

- Vehicle Testing Solutions & Support

New: Emission Pro and Pro+ Packages

For smarter brake emissions testing, LINK's Emission Pro and Pro+ are designed to meet the upcoming EURO regulation, GTR requirements, and beyond. LINK’s innovative design meets your future testing needs, including highly regenerative brake systems and low drag measurement capabilities.

Emission Pro and Pro+ packages provide a range of capabilities for testing brake emissions on passenger cars, commercial vehicles, and rail applications. Find out more by downloading the product brochure below:

Download Now: Emission Pro & Pro+

Visit Us

We would love to meet with you! Please stop by booth #402, schedule a one-on-one meeting with us, and visit our technical sessions. A complete list of special events can be found below.

LINK Technical Sessions

| Topic | Time | Room |

| Building the Bridge Testing Measurement and Tribology |

Sunday, September 25 4:40 p.m. |

Ballroom CD |

| Panel Discussion: Brake Standards |

Monday, September 26 8:30 a.m. |

Ballroom B |

| Testing and Measurement Methods for New Braking Technologies |

Monday, September 26 1:00 p.m. |

Ballroom B |

| Dynamometer Driving Cycle with Regenerative Braking, Corrosion, and Brake Drag Measurements (Oral Only) |

Monday, September 26 2:20 p.m. |

Ballroom B |

| Brake Systems for High Performance and Racing Application |

Tuesday, September 27 1:00 p.m. |

Ballroom B |

| Panel Discussion: Does High Performance Separate More from General Transportation with Respect to Brakes on Electrical Vehicles? |

Tuesday, September 27 1:40 p.m. |

Ballroom CD |

| Automotive Laboratory Partnership for Hardware-in-the-Loop Applications (ALPHA) (Oral Only) |

Tuesday, September 27 2:20 p.m. |

Ballroom B |

| Brake Emissions Measurement and Characterization |

Tuesday, September 27 3:20 p.m. |

Ballroom CD |

| Panel Discussion: Role of AI in Brake/Friction Testing Today and Future |

Wednesday, September 28 8:30 a.m. |

Ballroom B |

| Braking Issues Related to the Performance and Safety of Commercial Vehicles (Written Only) |

Wednesday, September 28 11:45 a.m. |

Ballroom B |

View the full event program here: https://www.sae.org/attend/brake/program/full-schedule